With the development of electronic products to miniaturization, multifunction and high performance, high-density 3D system integration technology came into being. Three-dimensional system integration makes assembly efficiency high, signal transmission speed fast and system reliability better. With these advantages, due to the huge energy consumption, it will also lead to an increase in heat per unit area of the substrate, and more and more attention has been put to dissipate heat. This puts forward higher performance requirements for heat dissipation materials of thermal interfaces. Through the heat dissipation design, the accumulated heat in the thermal interface of the electronic product is exported in time to maintain the working temperature within the reasonable design range, so as to ensure the system stability and reliability of the product. Thermal conductivity is used to describe the thermal conductivity of a material. The higher the thermal conductivity, the higher the thermal conductivity of the material. Therefore, the basic requirement of high-performance heat sinks materials is that the thermal conductivity is high enough.

The key features of the high-performance thermal conductive gaskets silicone rubber should generally meet the requirements of high thermal conductivity, good product reliability, good adhesion, convenient use, shock absorption and noise reduction, green environmental protection, etc. In addition to the basic thermal conductivity, the customer will also pay attention to the compression deformation, thermal resistance change, instantaneous pressure and long-term pressure of the heat-conducting gasket; For thin products, we will also pay attention to the operating performance of the product, mainly the size of the stripping force, etc.

Because the thermal conductive gasket is only used to fill the gap, the stress is very small, so the mechanical properties are generally not high, so the product is widely used. With the continuous improvement of the performance requirements of electronic products, the requirements for heat-conducting gaskets are becoming higher and higher. Thermal conductive gaskets will be continuously upgraded. Many explorations have been made, but the thermal conductivity is mostly below 3.0w/ (m · K), the formula is uncertain, which is seriously divorced from the actual product application, especially the research on reliability is less. In this experiment, the reactive silicone oil is used as the base material, and the high-performance heat-conducting filler is added to prepare the heat-conducting gasket with thermal conductivity of 4.0W/(m·K). The product has good usability and reliability and can meet the requirements of customers for high-performance heat-conducting gaskets.

1.1 Main raw materials and equipment

1.2 Preparation of silicone thermal pads

2.1 Performance index of heat-conducting gasket

2.2 Effect of thickness on compression deformation of the heat-conducting gasket

2.3 Effect of thickness on the thermal resistance of the heat-conducting gasket

2.5 The effect of peel force on the operational performance of thermally conductive gaskets

2.6 Reliability of thermal pads

XJY Silicones - First choice raw material supplier of silicone thermally conductive materials

1. Experiment

1.1 Main raw materials and equipment

Low viscosity vinyl silicone oil: viscosity 200mPa s, vinyl mole fraction 0.35%; high viscosity vinyl silicone oil: viscosity 5000mPa s, vinyl mole fraction 0.35%; hydrogen-containing silicone oil: viscosity 50mm2/s, active hydrogen mass fraction 0.1 %; modified silicone resin; platinum catalyst, inhibitor ; alumina: purity ≥99%, average particle size 20μm; aluminum nitride: purity 99.5%, average particle size 0.5μm; spherical oxidation Aluminum: purity ≥99.8%, average particle size 70μm. Double planetary mixer; oven, thermal cycle type, 。

1.2 Preparation of silicone thermal pads

Add 80 g of low-viscosity vinyl silicone oil, 8 g of high-viscosity vinyl silicone oil, 6 g of hydrogen-containing silicone oil, 5 g of modified silicone resin, 1.0 g of catalyst, and 0.2 g of inhibitor into the stirring tank, stirring for 0.5 h, and vacuuming to remove air bubbles; then add 55 g of aluminum nitride, stir for 0.5 h, then add 445 g of alumina, stir evenly, and then vacuum to remove air bubbles; finally, add 402 g of spherical alumina, stir for 0.5 h, and vacuum to remove air bubbles. The obtained paste is formed between the release films to a certain thickness, first vulcanized at 120° C. for 30 minutes, and then baked at 150° C. for 30 minutes to obtain a silicone thermal conductive gasket.

1.3 Performance Test

- Thermal conductivity: Using the TPS2500S thermal conductivity measuring instrument, tested according to ASTMD5470-2006.

- Thermal resistance: Using LW9389 thermal resistance meter tested according to ASTMD5470-2006.

- Hardness: Using the Shore OO type hardness tester.

- Density: Using the DPY-31 true density meter tested by helium true density method.

- Tensile Strength: Using the LS1 electronic universal testing machine tested according to ASTMD412-2006.

- Elongation at break: Using the ETM103A control electronic universal testing machine tested according to ASTMD412-2006.

- Volume resistivity: Using the 1508 insulation tester tested according to ASTMD257-2007;

- Relative permittivity: HJC-50kV breakdown voltage tester tested according to ASTMD150-2011;

- 180°peeling force: Tested by AR-1000 peel force tester.

- High-temperature aging property: Adopt Z120306 thermal cycle oven. Test method: The sample is placed at 150℃ for 440h and cooled to room temperature to test the thermal resistance;

- Cold and hot shock aging property: Tested by WIEETS60 high and low-temperature shock box. Test method: -40~125℃ for cold and heat cycle test, the sample is placed at -40℃ for 0.5h and then at 125℃ for 0.5h, this process is 1 cycle, a total of 440 cycles are tested and then cooled to room temperature to test the thermal resistance of the sample.

- Moisture and heat aging property: Use the KTHB-415TBS constant temperature and humidity box. The thermal resistance of the sample was measured after being placed at 85°C and 85% relative humidity for 440 hours and then cooled to room temperature.

- Instantaneous pressure: At the specified compression rate, the test reaches the specified compression deformation pressure.

- Long-term pressure: At the specified compression rate, the test maintains the specified compression deformation for more than 5 minutes.

2. Results and Discussion

2.1 Performance index of heat-conducting gasket

The thermal conductivity requirements of high-performance thermal pads are relatively high. Generally speaking, high thermal conductivity is achieved by a high amount of thermally conductive fillers. When the amount of thermally conductive fillers accounts for 90% of the total mass of the system, the thermal conductivity reaches 4.0 W/m•K; At this time, the density is 3.4g/cm3. Compared with the ordinary thermal conductive gasket, the elongation at break is obviously reduced, and the excellent electrical insulation performance is still maintained. The properties of the prepared silicone thermal pads are shown in Table 1.

| Table 1: Properties of Silicone Thermal Gaskets | |

| Test items | Performance |

| Thermal conductivity | 4.0 |

| 50 | |

| Density | 3.4 |

| Tensile Strength | 0.07 |

| Elongation at break | 25 |

| Volume resistivity | 1×1013 |

| Relative permittivity | 5.0 |

2.2 Effect of thickness on compression deformation of the heat-conducting gasket

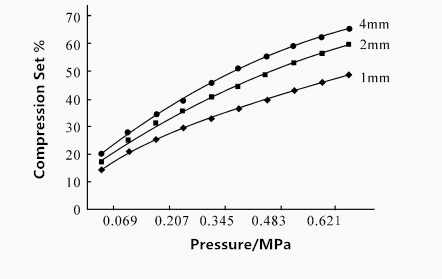

Compression deformation is also an important indicator of high-performance thermal pads. The greater the compression deformation, the better the flexibility of the product, the easier it is to fit tightly, and the smaller the interface thermal resistance, so as to achieve better thermal conductivity. Products with different thicknesses have different compression deformations. In general, the compression rate of compression deformation is 0.5mm/min. The effect of thickness on the compression deformation of thermal pads is shown in Figure 1.

Figure 1: Influence of Thickness on Compression Deformation of Thermal Gasket

It can be seen from Figure 1 that under the same pressure, the greater the thickness, the higher the compression set. Generally, the compression deformation of thick products is required to reach more than 60% (generally less than 0.69MPa), and products can be initially selected according to the compression deformation curve.

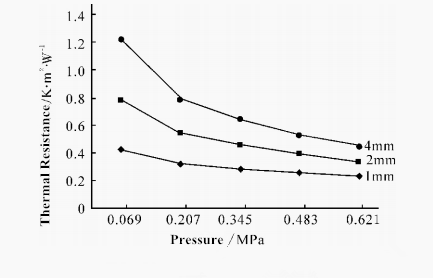

2.3 Effect of thickness on the thermal resistance of heat-conducting gasket

One of the characteristics of a high-performance heat-conducting gasket is low thermal resistance. The lower the thermal resistance, the better the heat-conducting effect. The thermal resistance of products with different thicknesses is different. See Fig. 2 for the influence of thickness on the thermal resistance of the heat-conducting gasket.

Figure 2 Effect of thickness on the thermal resistance of heat-conducting gasket

It can be seen from Figure 2 that the greater the product thickness, the greater the thermal resistance. The thermal resistance of products with the same thickness decreases linearly with the increase of pressure. The thickness of the product is determined by the design of the heat-conducting element. The width of the gap of the heat-conducting design unit corresponds to the thickness of the product

2.4 Effect of instantaneous and long-term pressure on the compressive deformation of thermally conductive gaskets

The results of the instantaneous and long-term pressure tests on the thermally conductive gasket are shown in Table 2.

| Table 2: Effect of instantaneous and long-term pressure on the compressive deformation of thermally conductive gaskets | ||

| Compressional deformation/% | Transient deformation/MPa | Chronic stress/MPa |

| 10 | 0.06 | 0 |

| 20 | 0.14 | 0.01 |

| 30 | 0.26 | 0.04 |

| 0.40 | 0.07 | |

| 50 | 0.51 | 0.09 |

| 60 | 0.68 | 0.11 |

Note: 1)Test rate 25.4 mm/min ,Thickness 2mm

Table 2 shows that at a compression rate of 25.4 mm/min, an instantaneous pressure of 0.259 MPa is required to achieve 30% compression deformation and a long-term pressure of 0.037 MPa is required to maintain 30% compression deformation. instantaneous and long-term pressures are close to the application and are very easy to use.

2.5 The effect of peel force on the operational performance of thermally conductive gaskets

With a high addition of thermally conductive fillers, the thermal conductivity of the thermal gasket is high, but the product becomes less strong in its own right, and in severe cases it also stains the electronic components and the product has environmental defects. Therefore, the design of high-performance thermally conductive gaskets must take into account the relationship between peel force and product operability. Generally speaking, thin products require higher workability than thick products. Even if the gasket does not contaminate the release film, a thin gasket with a high peel-off force will lift and displace the gasket during the removal of the film, affecting its use. The effect of peel force on the operability of the thermal conductive shims is shown in Table 3.

| Table 3: Influence of stripping force on the operability of heat conducting gasket | |

| Peeling force | Operability |

| 20 | Staining of release films |

| 12 | Non-staining release film, easy to displace |

| 8 | Non-staining release film, no displacement |

As seen in Table 3, for a 0.8mm thermally conductive gasket, the operation is poor when the peel force is greater than 12g/25mm, and best when the peel force is 8g/25mm. Because the thicker the product the easier it is to remove the release film, only thin products are discussed in this experiment.

2.6 Reliability of thermal pads

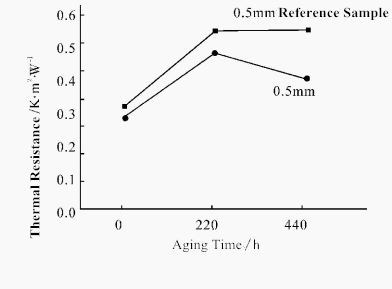

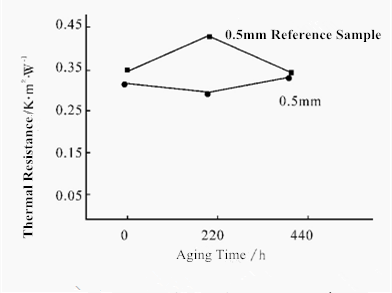

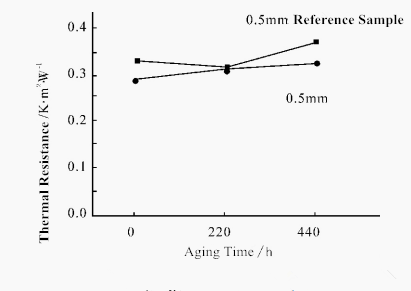

The upgrade of a new product generally requires a reliability comparison test. Reliability testing includes high-temperature aging test, thermal shock aging test and damp heat aging test. In the process of product upgrading, the customer requires that the thermal conductivity of the thermal pad should not be lower than that of the original reference sample after aging for 440 hours. The reliability test results are shown in Figure 3 to Figure 5.

Figure 3: High-temperature aging of heat-conducting gasket

Figure 4: Thermal shock aging of heat-conducting gasket

Figure 5: Heat and moisture aging of thermal conductive gaskets

It can be seen from Figure 3 to Figure 5 that the thermal resistance of the thermal pad is lower than that of the reference sample during the aging process of 150 ℃ for 440h; the thermal resistance of the thermal pad is lower than that of the reference sample during the thermal shock aging process of 440h; the wet heat aging process of 440h, the thermal resistance of the thermal pad is lower than that of the reference sample.

In summary, the upgraded reliability of thermal pads with the same thickness is better than that of the original reference samples.

3. Conclusion

A high-performance thermal pad is prepared by using reactive silicone oil as the base material and alumina and aluminum nitride as the thermally conductive filler. The preferred formula is: 80g of low-viscosity vinyl silicone oil, 8g of high-viscosity vinyl silicone oil, 6g of hydrogen-containing silicone oil, 5g of modified silicone resin, 1.0g of catalyst, and 0.2g of the inhibitor are added to the stirring kettle and stirred for 0.5h, and vacuumed to remove air bubbles; then add 55g of aluminum nitride, stir for 0.5h, then add 445g of alumina, stir evenly, and then vacuum to remove air bubbles; finally add 402g of spherical alumina, stir for 0.5h and vacuum to remove air bubbles. The thermal conductivity of the product prepared by this formula reaches 4.0W/(m·K), which is easy to operate and use, and has good reliability, which can meet the requirements of customers for high-performance thermal conductive gaskets.

XJY Silicones - First choice raw material supplier of silicone thermally conductive materials

| XJY Silicones, one of China's leading Silicone MQ resin and VMQ thermally conductive silicones manufacturers, has 30+ years of R&D and manufacturing experience and technical assistance of 15+ related patents in the silicone industry, also can customize the cost-effective thermally conductive silicone products according to the requirements of your electronic devices. |