As industries such as construction, electronics, power, automotive, and textiles increasingly demand materials with superior weather resistance, water resistance, and high reliability, the market for high-performance polymers used in waterproofing, moisture-proofing, and corrosion-resistant applications is experiencing rapid growth. Among various waterproofing materials, organic silicone MQ resin stands out due to its unique molecular structure and outstanding performance, making it a key raw material for technological upgrades and expansion into high-end markets in the silicone waterproofing industry. What is the market outlook for MQ silicone resin waterproofing applications?

MQ silicone resin possesses excellent properties such as UV resistance, aging resistance, high-temperature resistance, and waterproofing. Through research and development and large-scale production, it provides strong support for application areas such as waterproof coatings, silicone sealants, electronic packaging materials, textile finishing, and special coatings.

There are six aspects to introducing silicone MQ resin:

- What is silicone MQ resin?

- What is the mechanism of silicone waterproof performance?

- What are the advantages of MQ resin?

- What are the applications for silicone MQ resin?

- What is the future prospect of silicon MQ resin?

- How to choose Silicone waterproof products?

1. What is silicone MQ resin?

Silicone MQ resin is a special type of organic silicon polymer with a main structure composed of tetramethoxysilane (Q unit, SiO₄/₂) and trimethylsiloxane (M unit, R₃SiO₁/₂). The component in its molecular structure provides high rigidity and a three-dimensional spatial network, while the M unit modifies the molecular chain at the terminal end, enhancing flexibility and surface activity. This unique three-dimensional network structure confers high hydrophobicity, excellent weather resistance, and outstanding chemical inertness.

By adjusting the M/Q ratio, the molecular weight, structural density, physical properties, and application characteristics of MQ resins can be highly controlled, thereby meeting the diverse requirements of downstream industries such as waterproof coatings, silicone sealants, electronic encapsulation, and architectural coatings.

2. What is the mechanism of silicone waterproof performance?

(1) Superhydrophobicity derived from molecular structure

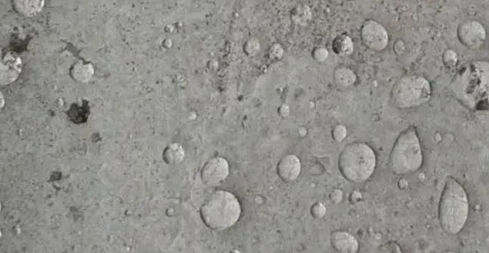

MQ silicone resins contain a large number of organic side groups such as methyl groups, significantly reducing the surface energy of the product (generally below 21 mN/m). This means water cannot form a continuous film on the surface but exists as spherical droplets, which easily slide off under gravitational force, thereby achieving a superhydrophobic effect and avoiding water damage.

(2) Durable waterproofing and weather resistance

Based on the Si-O-Si backbone structure, MQ resins exhibit exceptional resistance to environmental factors such as ultraviolet radiation, ozone, and extreme temperature fluctuations, including heat, maintaining the integrity and effectiveness of waterproof layers or surfaces over long periods of time. Conventional organic polymers often degrade and fail due to aging, whereas silicone resins remain stable even after prolonged exposure to rain, sunlight, and snow.

(3) Excellent adhesion and secondary processing performance

Thanks to the organic modification of the M unit, MQ resin achieves excellent adhesion to various substrates (glass, metals, ceramic, concrete, cellulose textiles, wood, etc.) through physical adsorption or chemical bonding. Additionally, MQ can serve as a functional additive in waterproof coatings, silicone sealants, and other materials, synergistically enhancing performance with various systems and providing mildew-resistant features for bath, kitchen, windows, bathrooms, and doors.

3. What are the advantages of MQ resin?

(1) Exceptional surface hydrophobic performance

After treatment with MQ resin, the water contact angle of substrates such as automotive glass, fabrics, and concrete can significantly exceed 100 degrees, achieving or even surpassing the “lotus effect,” preventing water penetration, wet issues, and secondary contamination.

(2) Outstanding UV aging resistance and temperature reversibility

Traditional organic waterproofing agents often fail rapidly when exposed to high temperatures, UV radiation, or extreme cold. The siloxane main chain structure of MQ resin maintains stable waterproofing performance in extreme temperature ranges from -50°C to 250°C, making it particularly suitable for outdoor buildings, automobiles, electronics, and other environments exposed to prolonged environmental conditions, providing protection in granite, paint, and foil seal applications.

(3) Excellent chemical corrosion resistance and pollution resistance

MQ silicone resin exhibits excellent inertness toward corrosive media such as acids, alkalis, solvents, and acid rain, and does not readily react with pollutants, thereby extending the service life of the waterproofing system and significantly reducing maintenance and replacement costs. Its proof performance makes it great for anti-mold, anti-mildew, and chemical protection.

(4) Good compatibility and adjustability

XJY's MQ silicone resin can be easily blended or modified with various organic/inorganic materials (such as PU, EVA, epoxy resin, etc.), greatly enhancing the functional diversity of various waterproof products, adding value and money saved over time.

(5) Non-toxic, environmentally friendly, and sustainable use

MQ resin is a halogen-free, low-VOC, environmentally friendly material that complies with global policies on green chemistry and sustainable development, making it particularly suitable for applications in food-grade packaging, medical devices (human contact), home decoration, and other fields. It is cured to be 100 silicone, good for hands, safe for work in various sectors.

4. What are the applications for silicone MQ resin?

(1)Waterproof coatings for construction projects

In waterproof layers for roofs, walls, basements, balconies, and other construction projects, MQ silicone resin is widely used as the main agent or modifying additive in elastic waterproof coatings. It can be blended with film-forming agents such as acrylic and polyurethane to enhance the coating's hydrophobicity, self-cleaning properties, and resistance to aging. Additionally, due to its small molecular size and stable waterproofing performance, it can easily penetrate and seal micro-cracks, enhancing the overall structural waterproofing reliability.

By using high-activity MQ resin composite waterproof coatings, roof waterproofing performance can be maintained for over 10 years. Even after exposure to wind, sun, and prolonged heavy rain, the surface remains intact with no water penetration, extending the maintenance cycle from 2 years to over 8 years, significantly reducing the maintenance burden for property management and owners, and providing great value for purchase and price.

(2) Waterproofing, Electrical Sealing, and Encapsulation Materials for Electronic Components

The electronics industry imposes extremely high requirements on the waterproofing, insulation, and stability of sealing materials. MQ silicone resin is widely used in products such as circuit board three-proof coatings, LED outdoor lighting power seals, and battery encapsulation adhesives to enhance moisture resistance, prevent sweat, condensation, or rainwater intrusion, and maintain long-term electrical insulation performance, providing a watertight seal and protection for high-value items and jobs.

(3) Waterproof and Self-Cleaning Coatings for Automotive Glass and Vehicle Covers

As a core component of automotive glass coatings, paint protection films (PPF), and interior waterproof coatings, MQ silicone resin endows materials with long-term superior waterproofing, anti-fog, and anti-soiling capabilities. Its exceptional waterproof coating not only prevents water stains from spreading and ensures driving safety but also reduces the adhesion of surface contaminants and dust, thereby extending vehicle cleaning intervals and maintenance, saving time and money.

(4) Waterproof finishing for textiles and leather fabrics

As a waterproof finishing agent for textiles and leather, MQ silicone resin can be uniformly coated on the fiber surface through processes such as immersion or spraying, imparting excellent water-repellent properties while retaining the original fabric's breathability and flexibility. It is widely applied in outdoor gear, protective clothing, sports shoes, and upholstery fabrics. Gloves and other protective textiles also benefit from mildew-resistant, anti-shrink, and durable properties, making them great for bathrooms, kitchens, and wet areas.

International sports apparel brands use the new generation of water-based MQ silicone resin for waterproofing treatment on outerwear fabrics. After 200 washes, the surface water-repellent rating remains above Level 4 of the ISO 4920 standard, far surpassing conventional treatment technologies. Some brands are available to purchase or buy on Amazon, offering consumers sets that are ready for home use.

(5) Waterproofing treatment for concrete, stone, and curtain wall components

MQ silicone resin can be used as a waterproofing agent for stone and concrete exterior walls. Through spraying or brushing techniques, it penetrates into the substrate, effectively blocking capillary water penetration, significantly enhancing the wall's stain resistance, freeze resistance, and self-cleaning, oil resistantance, weatherproof capabilities, while maintaining transparency and not altering the original appearance. This application is great for granite, wood, and metal surfaces.

(6) Corrosion Resistance and Salt Fog Resistance Applications

In applications such as ships, bridges, vehicle chassis, and guardrails that are exposed to high-salt and high-humidity environments for extended periods, MQ silicone resin-modified waterproof coatings and silicone sealants demonstrate exceptional corrosion resistance, effectively protecting steel structures from salt fog and chloride ion corrosion. For clients, this means longer durability and fewer refund issues due to leak or shrink failures.

5. What is the future prospect of silicon MQ resin?

(1) Expanding demand for environmentally friendly and green applications

With the global advancement of green manufacturing and sustainable development, solvent-free, water-based, low-VOC formulations, and biodegradable waterproof MQ resins will continue to be favored by the market. Especially in highly safety-sensitive industries such as food, healthcare, home furnishings, and preschool education building materials, environmentally friendly MQ materials hold promising prospects.

(2)Development of superhydrophobic and smart surface technologies

In the high-end waterproof coating field, superhydrophobic surfaces (contact angle over 150°) and self-healing surfaces are creating new markets. The Jiangxi Xinjia Yi team is collaborating with multiple university laboratories to develop a series of smart, responsive MQ resins, endowing them with self-healing, self-cleaning, and UV-resistant color-changing functions. This also brings easy maintenance tips to customers, since hands-on wax or additional items are not needed.

(3)Trend toward multifunctional composite materials

Future MQ silicone resins will integrate multiple properties such as antibacterial, wear-resistant, flame-retardant, and corrosion-resistant, expanding into high-tech industries like high-speed rail, aviation, 5G communications, and green cities, pushing waterproof materials to higher technological standards.

6. How to choose Silicone waterproof products?

Silicone MQ silicone waterproof resins, with their superior hydrophobicity, aging resistance, chemical resistance, long-term stability, and environmental friendliness, are becoming the core foundation of the next generation of high-end waterproof materials. How to enhance product competitiveness?

XJY Silicone is one of China's leading manufacturers of silicone MQ resins and VMQ silicones, with over 30 years of R&D and manufacturing experience in the silicone industry. The company holds more than 15 related patents and technical support, and its silicone raw material products can meet the needs of the waterproofing sector, offering diverse customized solutions and great prices. You can buy or purchase these products anytime.

If you have any inquiries regarding silicone MQ resin product technology, customization, or sample requests, please feel free to contact us at any time. Let’s collaborate to unlock a new future of material innovation and value-driven collaboration!